Direct Card Printer Dye-Sublimation Printers |

|

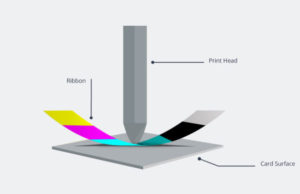

| Popularly known as “dye sublimation printers”, these printers are the most common that uses cards and ink ribbons to print. The printhead used in it incorporates small pixels of glass that prints directly on the cards by applying the ink onto the cards. In this type of printing process, you will find a small white border around the corners as printhead can’t go over the card’s’ edges. Direct-to-card printers has lowest cost per card and gives you the faster print speed. These machines are manufactured specially to print onto frequent adhesive-backed and PVC cards. Benefits – Decreases the front cost. |

Retransfer Card Printer Over-the-Edge Printers |

|

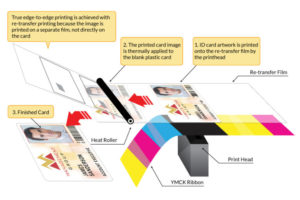

| Known by names like “over-the-edge”, “reverse transfer”, or “high-definition printer”, these printers print scene. Specially designed to print on cards with irregular surfaces and technology and non-technology cards. Retransfer printers uses film and ink ribbon to print the cards. At the point when the cards go into the printer, no contact occurs between printhead and the cards. Rather, the ink gets imprinted onto the backside of a clean film, and that film is then laid and warmed onto the cards. This enables the ink to be imprinted on the whole surface of the cards, generally called “full drain.” They are slower than Direct-to-card printers and will have a marginally higher cost for every printed card because of the way they utilize its different components. This kind of printing will give you the best picture quality and, in addition, more strong cards than the direct-to-card printers. Benefits – Better quality of the printed images. |

CONTACT US